The QCM-I and QCM-I Mini systems are designed to be modular so that they can be configured to use the sensors and sample environments that are most appropriate for the user’s experiments.

This technical note summarizes the basic configurations that can be used with the QCM-I for measuring the effect of changes in humidity on thin films. The humidity measurement uses a humidity control instrument, which allows for straight forward, active humidity control in a format which can be used across multiple experimental setups and is not just limited to QCM-I measurements.

Experimental Setups for Humidity control

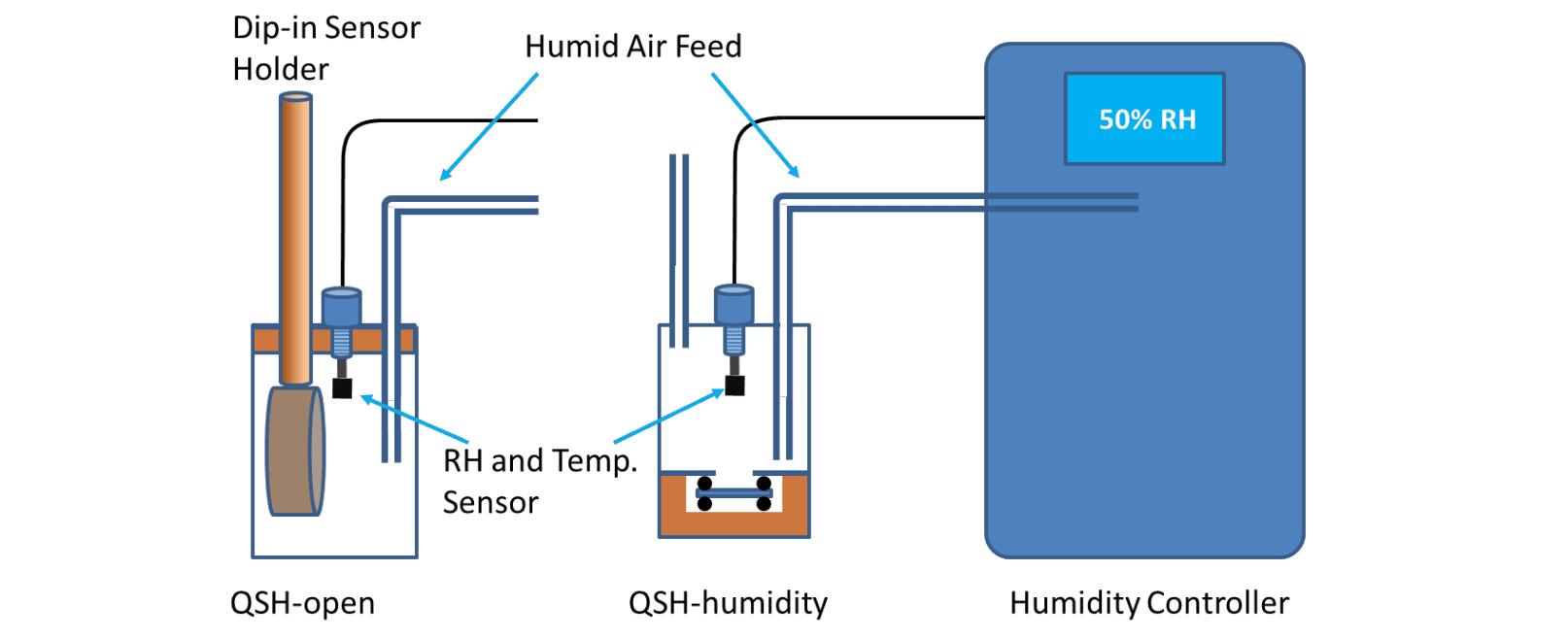

Humidity controlled experiments are run by passing controlled humidity air over the QCM sensor surface. The humidified gas is produced using a stand-alone humidity control unit, with an RH sensor at the sample to actively maintain the set RH value. QCM sensors can be measured in two different formats, using the dip-in sensor holder QSH-open in a glass cell at room temperature, or with the flow cell QSH-humidity in the QCM-I thermal chamber.

INTEGRATED DESICCANT SYSTEM Ambient air is dried through a specially designed automatic recycling desiccant system, providing humidity control for months at a time, with no requirements for a costly dry air supply.

INERT GAS REGULATOR Alongside dry air, the RH95 can now be pumped with dry nitrogen with the addition of the inert gas regulator.

COMPACT DESIGN The small size of the controller conserves vital benchtop space and provides a neat compact humidity system.

SENSOR AT POINT OF SAMPLE A sensor is mounted inside the chamber to create a feedback loop to the controller, ensuring precise control of RH between 5%-90% (dependent on chamber type).

MULTI-CHAMBER COMPATIBILITY It is compatible with a variety of sample chambers and is supplied with a small sealed chamber for use in sensor validation as standard.

VALIDATION A variety of certified salt solutions are available to accurately validate the humidity sensors.

Technical Note By: Dr M. J. Swann 4/2020